Incubation Cluster

Defossilation

Global economy and thus growth and wealth of humankind is highly dependent on the use of fossil resources. These fossil resources (coal, crude oil, and natural gas) are predominantly used as energy source and, to a significantly lower extent, for the production of material goods like plastic bags, running shoes and complex pharmaceuticals.

The burning of fossil resources results in billions of tons of CO2 emissions annually and is thus the main reason for anthropogenic climate change and its entailed challenges to humankind.

To mitigate climate change, many nations all over the world are now planning to tremendously shift the demand for fossil resources to renewable alternatives. This global scientific and economic endeavor to move away from fossil resources in energy and materials production is coined “Defossilation” and acts as the name giver of our Incubation Cluster.

The Cluster comprises our activities which aim to support industries to become independent of fossil raw materials. Key in the transformation towards a climate neutral society are

- efficient recycling technologies which enable circular economies.

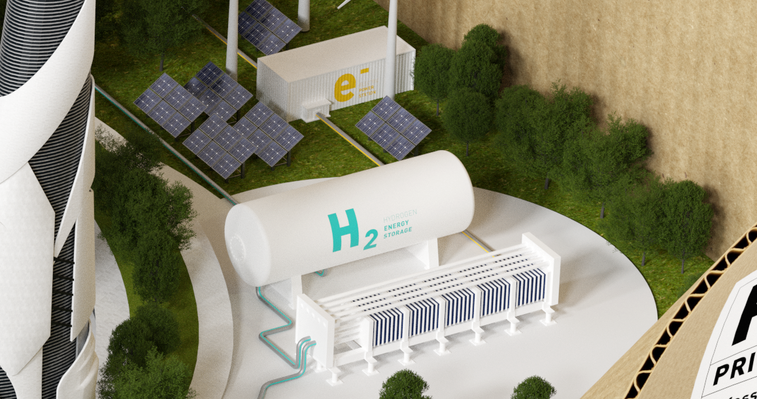

- a green hydrogen economy which affords the cost competitive production of climate neutrally produced hydrogen and a fully functional H2 ecosystem.

- technologies to capture and utilize CO2 and replace current feedstocks with sustainable alternatives.

We at Creavis strive for innovation in all three key areas!

In a circular carbon economy “waste products” need to be collected and sorted. Part of the sorted waste can directly be recycled into new base materials. However, due to impurities these recycled materials are typically of lower quality (so-called “downcycling”). Therefore, up to today, fossil resources are still needed to create high-quality materials.

This is where the New Growth Area (NGA) Circularity comes into play: The circularity team aims to provide new additives and materials to prevent downcycling and thus strives to enable a high-quality mechanical recycling.

However, many other waste streams, like residues of mechanical sorting are too heterogeneous for a mechanical recycling approach. Therefore, new ways of chemical recycling are needed to guarantee a circular economy. This method utilizes the possibility to break the polymer’s chemical bonds to transform the waste into lower molecular weight streams or ideally its monomers. Subsequently, these can be used as “virgin” feedstocks for corresponding chemical processes to create new materials. At Creavis, we develop new solutions in chemical recycling processes for the recycling of various polymers.

But not only polymers need to be recycled. The upcoming electrification, especially of cars, requires substantial amounts of lithium for batteries. Today, this lithium is not reused and new efficient technologies for the recycling of lithium are required to close the loop here. At Creavis we drive innovation in the fields of metal recycling and of mechanical and chemical recycling of polymers. With this we aim to promote a circular economy which turns waste into valuable materials thus reducing the need for fossil raw materials. This is an important measure to mitigate climate change and foster a society which is independent of fossil fuels.

Defossilation describes the transformation of industries to cut CO₂ emissions and eventually reach „net zero” and an emission-free society. This can only be achieved by replacing processes that release greenhouse gases and compensating any CO₂ emissions that cannot be cut. For example, even in a circular economy with very efficientrecycling technologies, there will be waste streams too poor for further reuse which need to be gasified, causing CO and CO₂ emissions.

To reduce these emissions avoiding rising CO₂ emission fines and seeking to stop climate change, the greenhouse gas needs to be captured and stored. Even better would it be to use the gas, transforming it into new chemicals. To achieve this, new approaches to capture and utilize the carbon atoms in carbon oxides are needed. At Creavis, the Renewable Carbon team is dedicated to innovations that aim to do exactly that. The team aims to combine existing Evonik product platforms to separate CO₂ from gas streams and to develop chemical and biotechnological processes that activate and utilize CO₂ as chemical feedstock. The product of such processes: New chemicals with zero or negative carbon footprint.

Plants show us an alternative pathway to capture and utilize CO₂. Here the natural photosynthesis uses the CO₂ for the plant growth. We want to learn from nature by using both artificial and natural photosynthesis to identify new sustainable feedstocks for Evonik and the chemicals industry.

The world is on its way to a sustainable hydrogen economy.

Besides the chemical also other industries like the energy or steel industry as well as the mobility sector will need substantial quantities of climate-neutral hydrogen in a post-fossil world. For example, the chemical industry can use climate-neutral hydrogen as chemical feedstock to produce sustainable base chemicals with CO and CO2.

Climate-neutral hydrogen can be produced via water electrolysis with renewable power supply. Therefore, it is the task of our Hydrogen Economy team to provide specialty chemicals and materials to enable on one hand the cost-efficient production of green hydrogen and on the other hand the entire future hydrogen economy.

The upcoming hydrogen economy will create new value chains demanding novel material solutions, like for ultra-low temperature liquid or high-pressure gaseous hydrogen transportation and storage.

A functioning sustainable hydrogen economy is key to a net-zero emission free society and therefore Creavis drives innovations in various focus areas to contribute to this overall goal.

Current Defossilation Projects

DURAION® FOR SUSTAINABLE HYDROGEN PRODUCTION

We are meeting the global challenge of the energy transition with our solutions in the field of the green hydrogen economy. At Creavis, researchers have developed the anion exchange membrane DURAION® which aims to enable the cost-competitive production of green hydrogen thus leasing the way into a sustainable hydrogen economy.

Blue Lithium - Lithium from spent batteries

We are developing a marketable membrane-based technology to enable the recycling of lithium from end-of-life batteries of electric cars. This is the only way to make the mobility revolution truly sustainable.

Project Rheticus - Artificial Photosynthesis

With the innovative technology of artificial photosynthesis, which is behind Rheticus, valuable specialty chemicals are to be produced sustainably - from carbon dioxide (CO2) and electricity from renewable sources with the help of bacteria. By using CO2 as a raw material, Rheticus can reduce dependence on fossil raw materials.

Circular Polyurethane Solutions

Every year, 40 million mattresses are thrown away in Europe alone. The result: vast amounts of waste that is hardly ever recycled. Our new process turns polyurethane foams back into their individual components and will help solve one of the major waste problems of our time.