NextGen Additives for Battery Materials:

Paving the Way of Electromobility

The future of mobility is electric. The rapid growth of the electric vehicle (EV) market, with nearly 14 million units sold globally in 2023, underscores the urgency of addressing the challenges of electromobility. Nearly 1 in 5 new cars sold is now electric, and this figure is expected to rise to 1 in 2 by 2030.

Driving range, fast-charging capabilities, sustainable production, affordability, and safety are pivotal issues that must be resolved to ensure the widespread adoption of EVs. Central to these challenges is the development of advanced battery technologies, which are crucial in driving the future of electromobility.

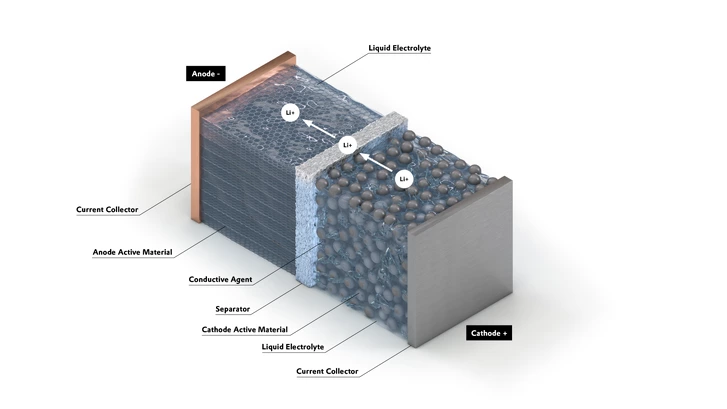

Understanding Battery Basics

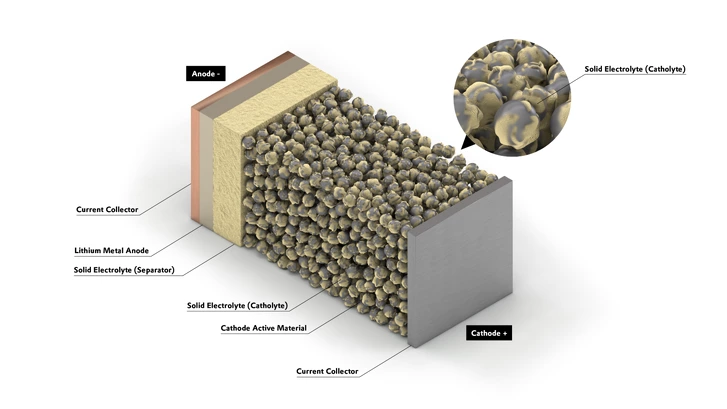

At the heart of every electric vehicle lies the battery, a system composed of several key components: the cathode, anode, electrolyte, and separator. Each component plays a critical role in determining the battery's performance, safety, and longevity. As the demand for more efficient and sustainable batteries grows, so does the need for innovative materials and additives that enhance these fundamental components.

Established Competencies of Evonik

Evonik, a global leader in specialty chemicals, offers a comprehensive product portfolio that supports the battery value chain. From smart materials and specialty additives to process enablers and ready-to-use products, Evonik’s solutions significantly improve the performance, longevity, and safety of EV batteries. High-performance materials like AEROXIDE® fumed metal oxides for enhanced battery safety and durability, and TEGO® SURTEN E series as process enablers, exemplify Evonik's commitment to advancing battery technology. These are just a few examples from a broad range of innovative solutions.

Next Generation Solutions by Creavis

Creavis, Evonik's strategic innovation unit, is at the forefront of developing next-generation additives for batteries. This program focuses on addressing the critical challenges faced by the electromobility market, particularly in the field of inactive battery materials and specialty additives which are key enablers for emerging battery cell technologies such as solid-state or sodium-ion batteries.

Solid-Polymer Electrolyte Additives

One of the key innovations from Creavis is the development of solid-polymer electrolyte additives. Traditional liquid electrolytes in batteries limit the choice of high-performance active materials, such as lithium metal, are prone to leakage, and can become volatile in the event of a thermal runaway, posing significant safety risks. By replacing the liquid electrolyte with solid-polymer electrolytes, these shortcomings are addressed. However, ionic conductivity in solid-polymer electrolytes has traditionally been low. Our new additives offer enhanced ionic conductivity and mechanical stability, significantly improving battery safety and durability.

Next-Gen Sustainable Binder

Another groundbreaking solution is the development of next-generation sustainable binder materials. Designed to be more eco-friendly and compatible with non-toxic solvents, these binders reduce both costs and environmental impact of battery production aligning with global efforts to create more environmentally responsible manufacturing processes. At the same time, by improving the mechanical and electrochemical properties of the electrodes, they ensure better performance and longevity of the batteries.

Electrolyte Additives for High Energy and Durable Batteries

Creavis is also developing electrolyte additives that boost the durability and longevity of batteries. These additives enhance the electrochemical stability of the electrolyte, allowing for the use of active materials with higher performance and resulting in longer battery life. This innovation is crucial for extending the range of electric vehicles and improving their overall lifetime.

Exploring Other Promising Technologies

In addition to these core innovations, Creavis is exploring other promising technologies such as dry coating and sodium-ion batteries. Dry coating techniques can reduce the need for solvents in battery manufacturing, making the process more sustainable and cost-effective. Sodium-ion batteries present an alternative to lithium-ion batteries, utilizing more abundant and potentially cheaper raw materials. We are always looking for novel opportunities in the area of battery materials and seeking to collaborate with external partners such as start-ups or academia.

Future Demand and Market Outlook

In 2023, global investment in EV batteries soared to a total of $115 billion. Over the past five years, 2 TWh of lithium-ion battery (LIB) capacity was added worldwide, powering more than 40 million EVs. By 2030, EV batteries will be responsible for displacing 8 million barrels of oil per day and, together with storage applications, will directly contribute to nearly 20% of emissions reductions.

By leveraging its deep expertise and innovative spirit, Creavis is not only addressing the current challenges of the electromobility market but also paving the way for a more sustainable and electrified future. The "NextGen Additives for Battery Materials" program exemplifies Evonik's commitment to leading beyond chemistry, creating solutions that improve life today and tomorrow. As Creavis we are always searching for new collaboration partners to foster the development of novel battery materials.